3d porous ceramic li s battery

Diffusion-Controlled Porous Crystalline Silicon Lithium Metal Batteries. In contrast the initial discharge capacity of LiLLZOPEOS battery is 663 mAhg 1 but the capacity retention is only 64 after 100 cycles.

Recent Advances And Strategies Toward Polysulfides Shuttle Inhibition For High Performance Li S Batteries Huang 2022 Advanced Science Wiley Online Library

Researchers from Carnegie Mellon University and the Missouri University of Science and Technology have developed a new technique for 3D printing battery electrodes that could dramatically improve the capacity of lithium-ion batteries as well as charging rates.

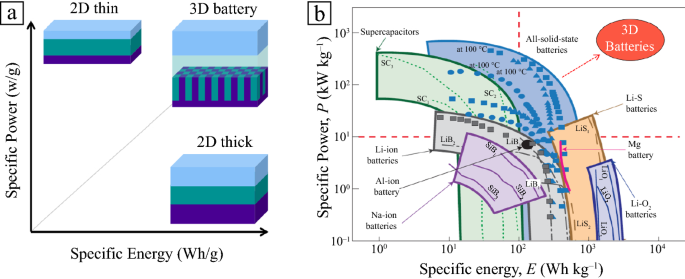

. Among many types of batteries Li-ion and Li-S batteries have been of great interest because of their high energy density low self-discharge and non-memory effect among other aspects. Ceramics International 2019 45 8 10572-10580. Hierarchal 3D porous components produced by AM methods may facilitate ion transport and yield higher power and energy densities owing to an increased surface area and improved electrolyte.

ArticleLiu2019HierarchicalPC titleHierarchical porous ceramics with 3D reticular architecture and efficient flow-through filtration towards high-temperature particulate matter capture authorJingjing Liu and Bo Ren and Yali Wang and Yuju Lu and Lu Wang and Yugu Chen and Jinlong Yang and Yong Huang journalChemical Engineering Journal year2019. By in situ polymerizing poly ethylene glycol methyl ether acrylate within self-supported three-dimensional porous Li 13 Al 03 Ti 17 PO 4 3 framework the as-assembled solid-state battery employing 45 V LiNi 08 Mn 01 Co 01 O 2 cathode and Li metal anode demonstrates a high Coulombic efficiency exceeding 99 at room temperature. Three-dimensional 3D grid porous electrodes introduce vertically aligned pores as a convenient path for the transport of lithium-ions Li-ions thereby reducing the total transport distance of Li-ions and improving the reaction kinetics.

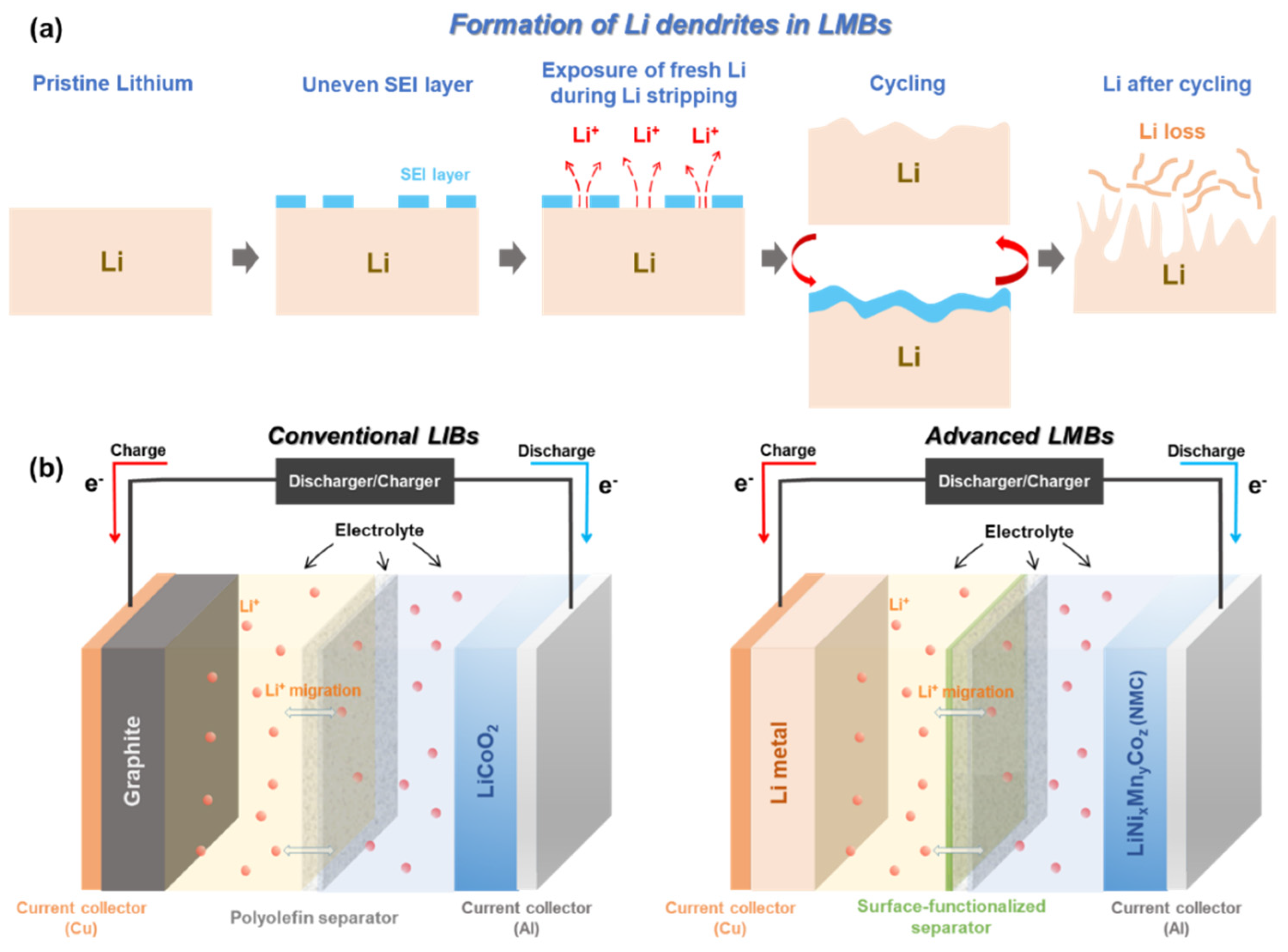

Achieving carbon-rich silicon-containing ceramic anode for advanced lithium ion battery. Meanwhile 3D porous host materials for Li metal anodes have been studied as another strategy including conductive 3D hosts such as surface modified Li metal 33 Cu substrates 3436 ZnO-coated polyimide nanofibers 37 Si-coated porous carbon 38 reduced graphene oxides 3940 as well as non-conductive 3D hosts such as polyacrylonitrile PAN. Micro-porous polyolefin separators such as PE and polypropylene PP are commonly used in.

The work aimed to develop 3D porous SS 316L electrode with large surface area and porosity to promote the electrochemical properties of SS 316L electrodes. Although there have been other studies focusing on 3D electrodes fabricated by 3D printing there still exists a gap between electrode design and their. The innovative method recently published in the journal Additive Manufacturing is capable of.

This can be attributed to the introduction of. Department of Energys Office of Scientific and Technical Information Development of Porous Sintered-Ceramic Separators for Application in a Li--AlLiCl-. A Celgard polymer separator was used in the device to improve the performance of the battery and demonstrate the ability to integrate 3D.

The lithium-ion battery powered LED bangle that was 3D printed by the team at Duke University. Li and Ji-quan Yang journalJournal of the European Ceramic Society year2022. Lithiated TM oxides have long been mass-manufactured in Li-ion batteries in which bulk-processed ceramics are combined with conductive carbon coatings to mitigate low electronic conductivities.

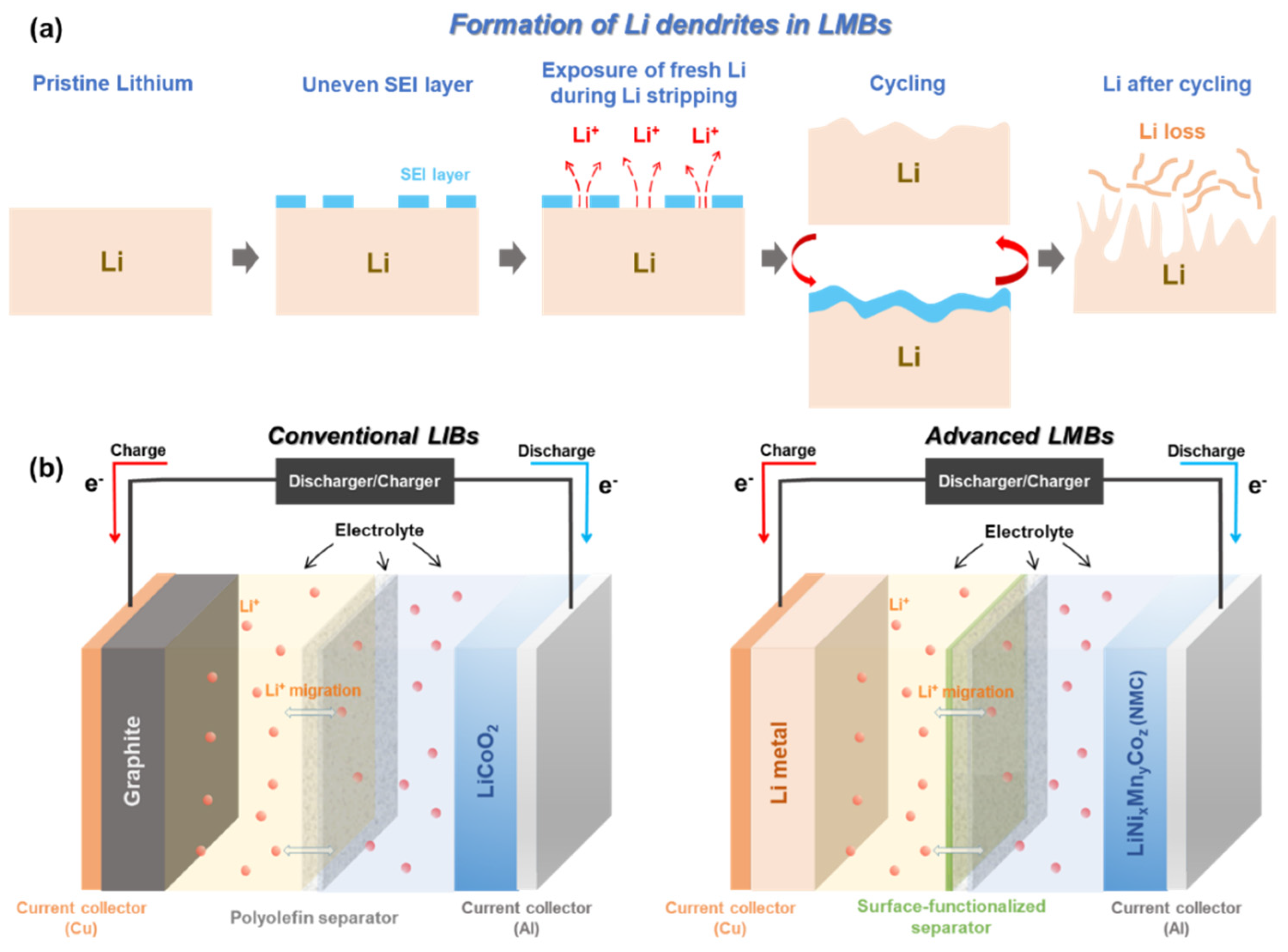

IScience 2020 23 10. Li batteries Li-S Li-O 2 and advanced LIBs use Li metal as common anode and S O 2. Emerging applications require batteries with higher performance factors such as capacity and cycling life which have motivated many research efforts on constructing high-performance.

Ad Free UK Delivery on Eligible Orders. Although there have been other studies focusing on 3D electrodes fabricated by 3D printing there still exists a gap. The initial discharge capacity of LiPTFELLZOPEOS battery is 655 mAhg 1 and the discharge capacity remains at 568 mAhg 1 after 100 cycles with a capacity retention of 86.

Three-dimensional 3D grid porous electrodes introduce vertically aligned pores as a convenient path for the transport of lithium-ions Li-ions thereby reducing the total transport distance of Li-ions and improving the reaction kinetics. Engineering Bamboo Leaves Into 3D Macroporous email protected. A review of 3D printed porous ceramics articleZhang2022ARO titleA review of 3D printed porous ceramics authorFengduo Zhang and Zongan Li and Mengjia Xu and Shiyan Wang and N.

Hereafter called LAGP ceramic for developing 3D ion conducting structure. They performed the DMLS process systematically and fabricated 25 cylindrical samples with varying laser power 30 W to 90 W and scan speeds 300 mms to 1500 mms.

Nanomaterials Free Full Text Surface Functionalized Separator For Stable And Reliable Lithium Metal Batteries A Review Html

C Free Full Text Graphene Enhanced Battery Components In Rechargeable Lithium Ion And Lithium Metal Batteries Html

Batteries Supercaps Vol 3 No 8 Chemistry Europe

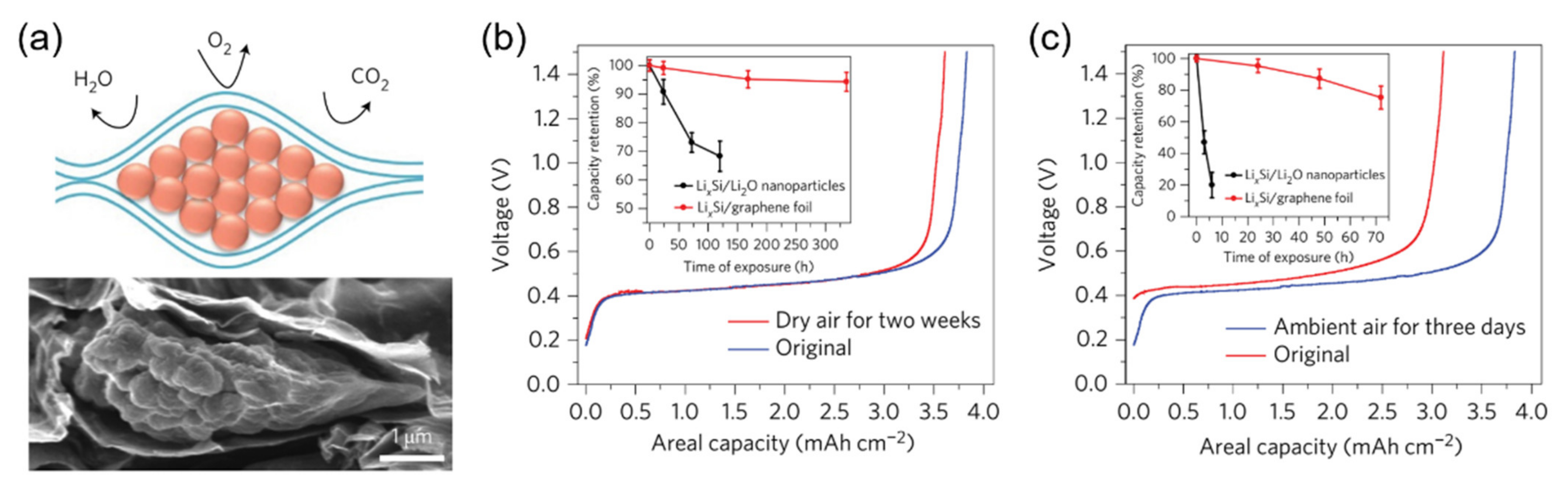

Processes Free Full Text N Doped Porous Carbon Microspheres Derived From Yeast As Lithium Sulfide Hosts For Advanced Lithium Ion Batteries Html

Challenge And Strategies In Room Temperature Sodium Sulfur Batteries A Comparison With Lithium Sulfur Batteries Lin Small Wiley Online Library

Atomic Scale Insights Into Comparative Mechanisms And Kinetics Of Na S And Li S Batteries Acs Catalysis

Lithium Sulfur Batteries From Liquid To Solid Cells Journal Of Materials Chemistry A Rsc Publishing Doi 10 1039 C4ta04727c

Processes Free Full Text N Doped Porous Carbon Microspheres Derived From Yeast As Lithium Sulfide Hosts For Advanced Lithium Ion Batteries Html

Improving Energy Storage With Sulfur Polymer Cathodes

Lithium Sulfur Batteries From Liquid To Solid Cells Journal Of Materials Chemistry A Rsc Publishing Doi 10 1039 C4ta04727c

Lithium Based Vertically Aligned Nanocomposites For Three Dimensional Solid State Batteries Springerlink

Lithium Sulfur Batteries From Liquid To Solid Cells Journal Of Materials Chemistry A Rsc Publishing Doi 10 1039 C4ta04727c

Lithium Sulfur Batteries From Liquid To Solid Cells Journal Of Materials Chemistry A Rsc Publishing Doi 10 1039 C4ta04727c

Atomic Scale Insights Into Comparative Mechanisms And Kinetics Of Na S And Li S Batteries Acs Catalysis

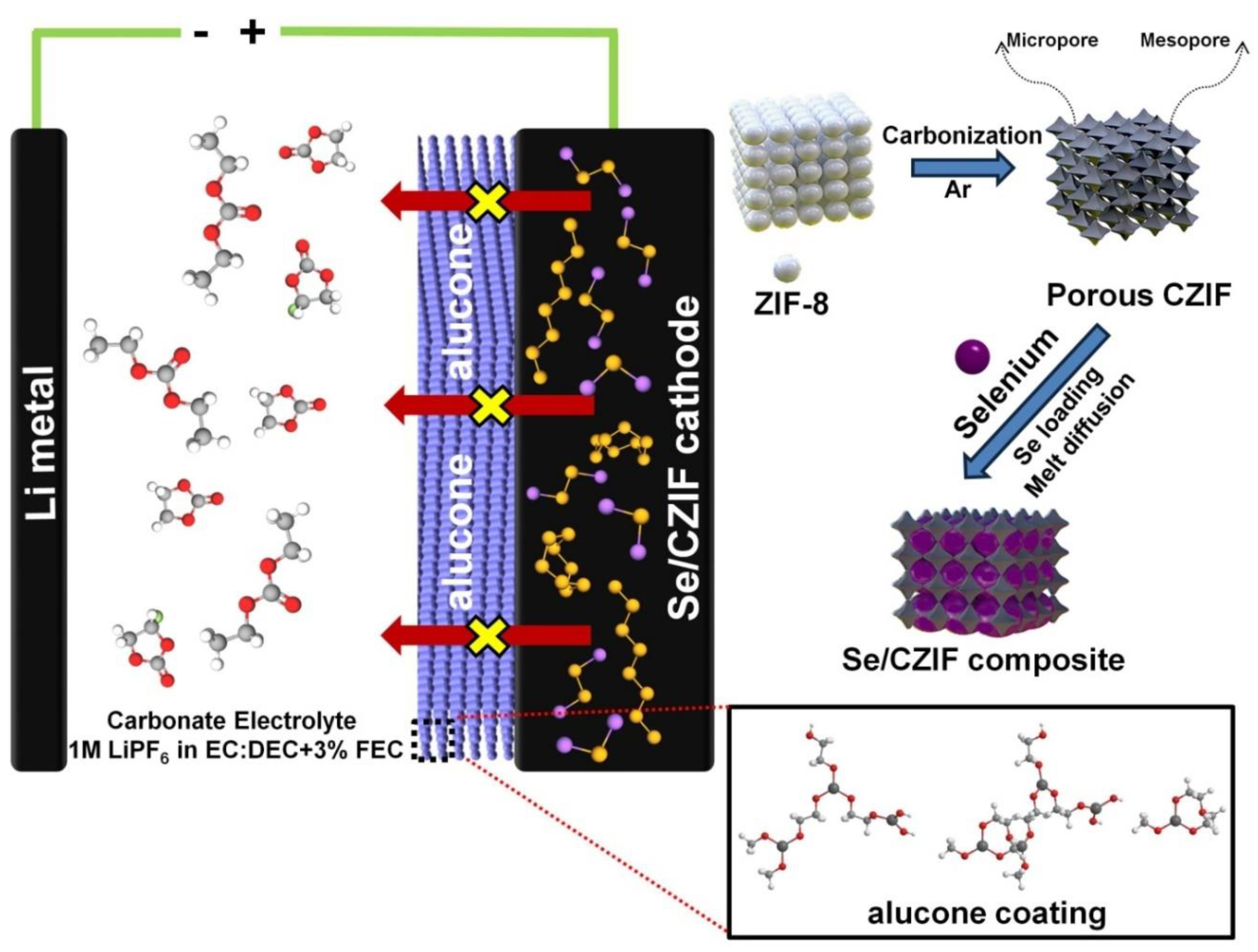

Nanomaterials Free Full Text Durable Lithium Selenium Batteries Enabled By The Integration Of Mof Derived Porous Carbon And Alucone Coating Html

Enhanced Sulfur Redox Kinetics By Hollow Structured Nico2o4 Entangled With Acidified Mwcnts For Lithium Sulfur Batteries Springerlink

Li1 5al0 5ge1 5p3o12 Conductive Ceramic Separator Sheets With Optional Size For Li Air Solid Rechargeable Batteries Eq Lagp Ld